LASER CUTTING

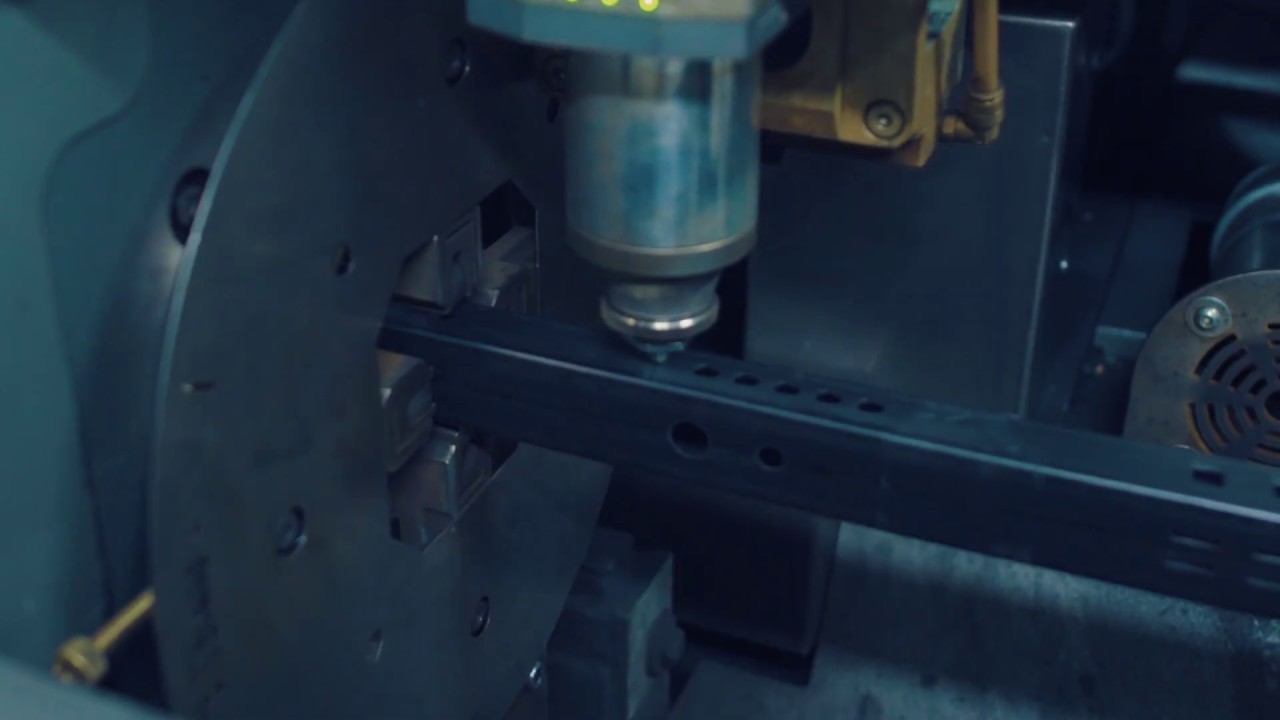

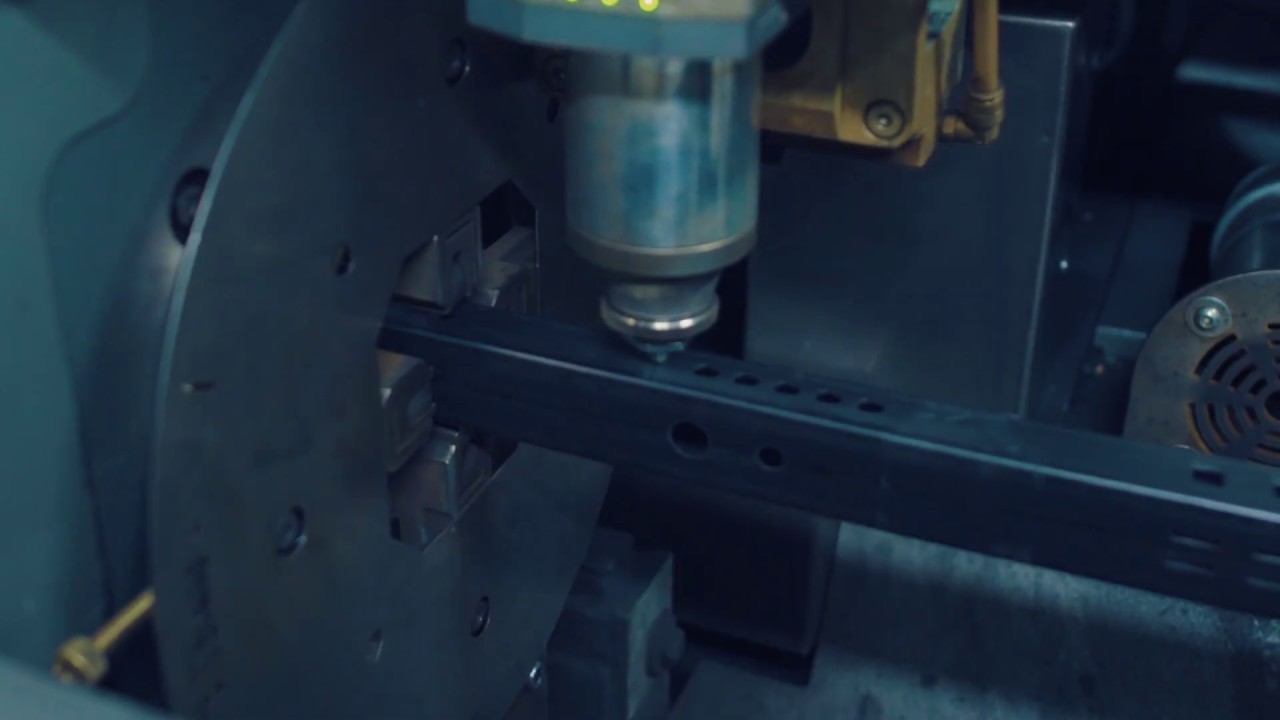

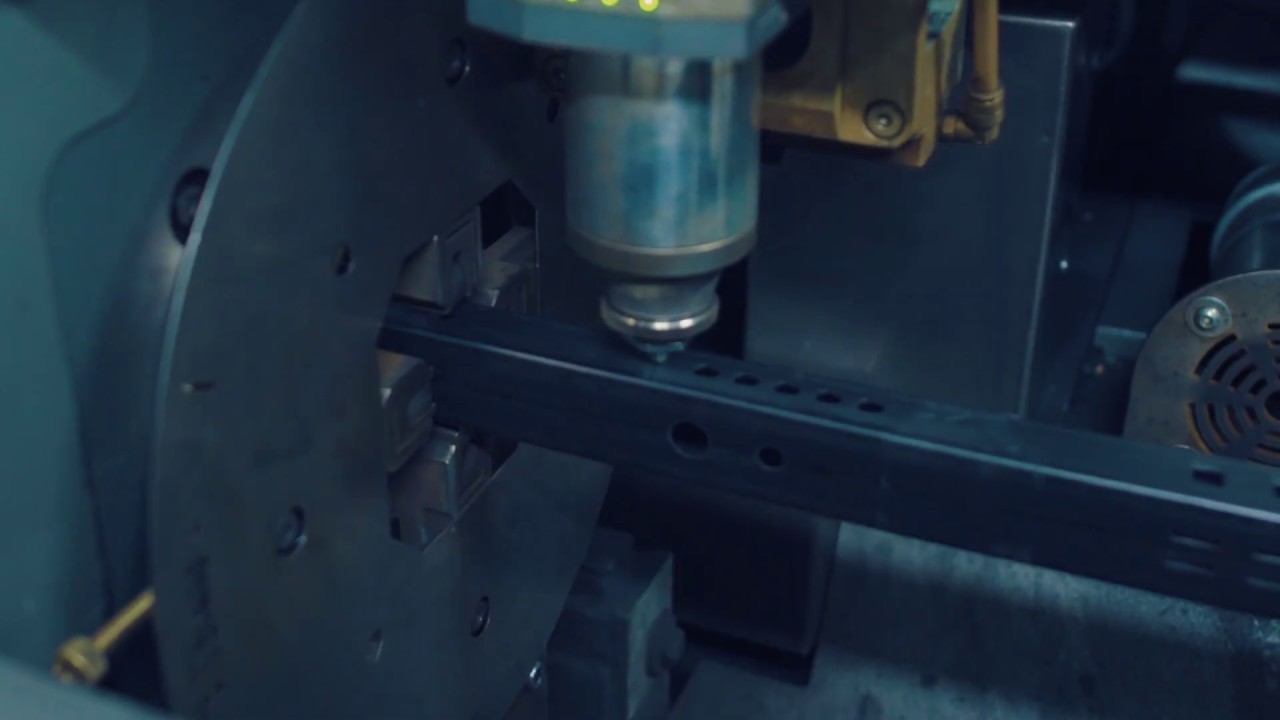

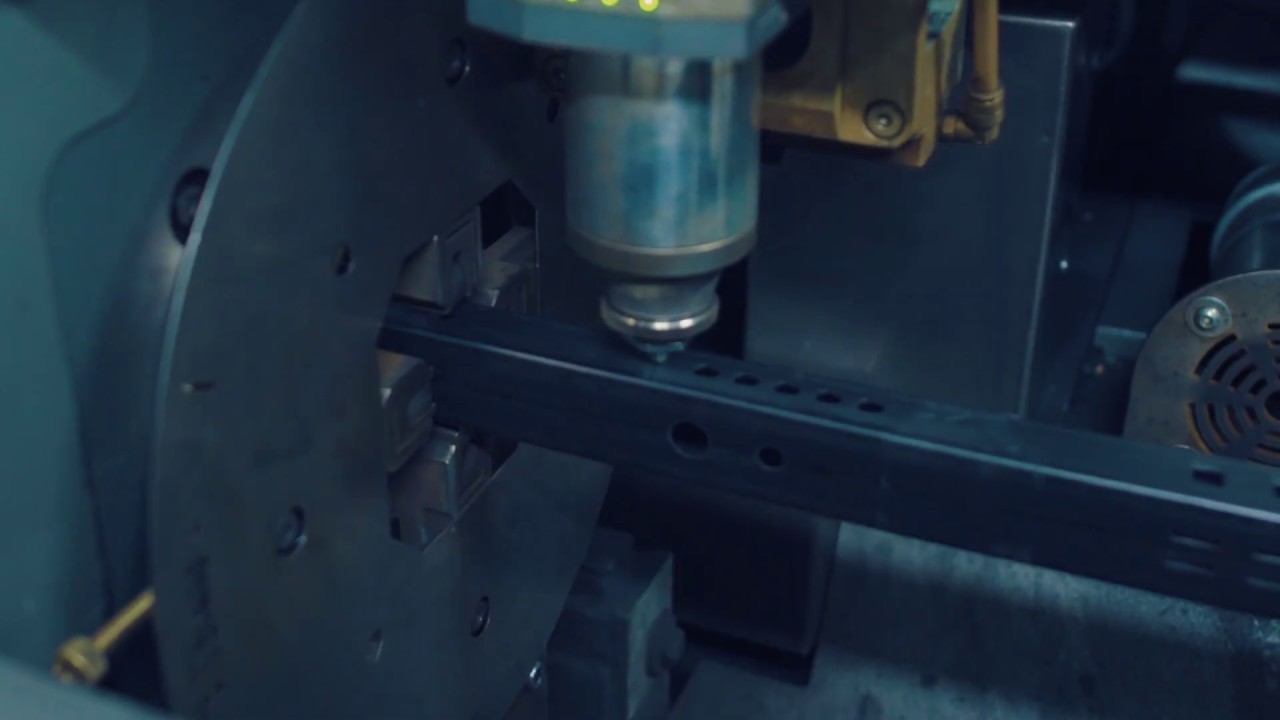

Our machine park has been equipped with modern devices that enable maximum technological efficiency while maintaining the best time and energy parameters. Such criteria in the laser cutting process are fulfilled by the dual-function BLM LC5 laser

It gives the possibility of processing sheets in sizes of 3000 mm x 1500 mm, pipes with a diameter of up to 120 mm and profiles with a diagonal not exceeding 130 mm. The advantage of Fly-Cut technology in thin sheet cutting i.e. materials up to 1.5mm in thickness is such that you can process material up to 50% faster than in conventional piercing routines. All laser cuttings are supervised by qualified technicians. Their knowledge and skills are the guarantee of precise process execution and the highest quality with repeatability in production of elements.

LASER CUTTING

LASER CUTTING

Our machine park has been equipped with modern devices that enable maximum technological efficiency while maintaining the best time and energy parameters. Such criteria in the laser cutting process are fulfilled by the dual-function BLM LC5 laser

It gives the possibility of processing sheets in sizes of 3000 mm x 1500 mm, pipes with a diameter of up to 120 mm and profiles with a diagonal not exceeding 130 mm. The advantage of Fly-Cut technology in thin sheet cutting i.e. materials up to 1.5mm in thickness is such that you can process material up to 50% faster than in conventional piercing routines. All laser cuttings are supervised by qualified technicians. Their knowledge and skills are the guarantee of precise process execution and the highest quality with repeatability in production of elements.

LASER CUTTING

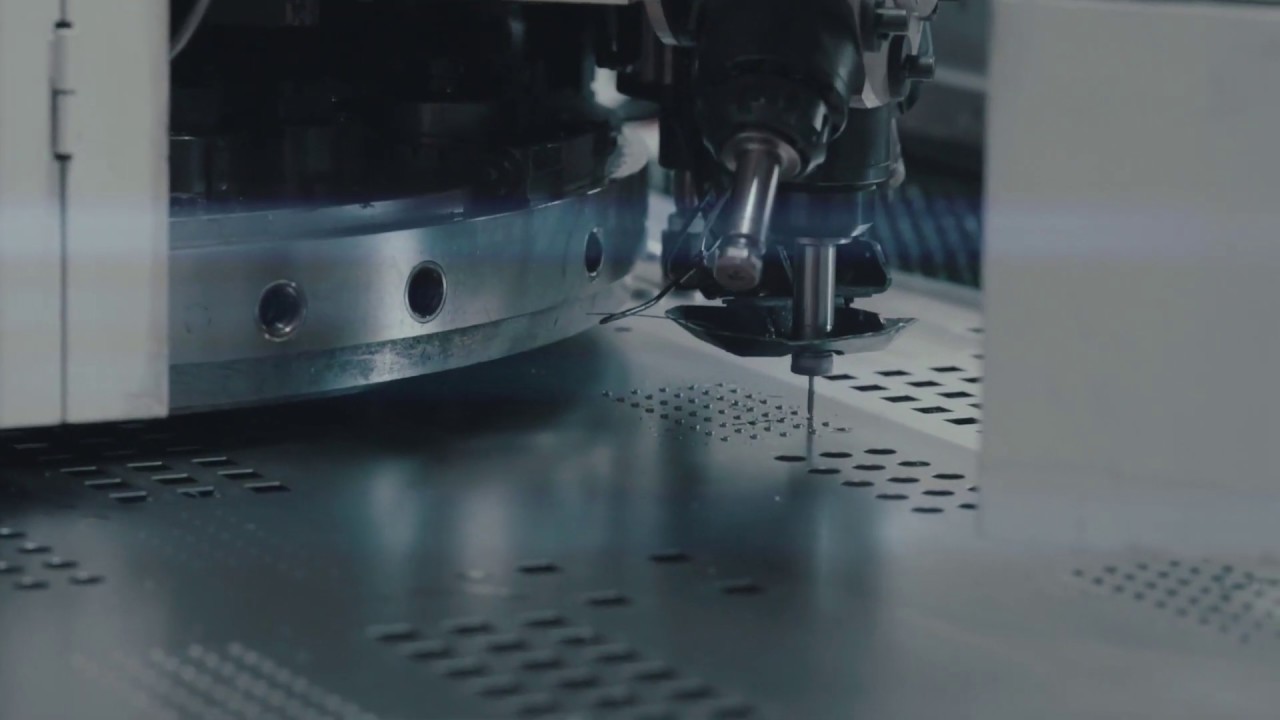

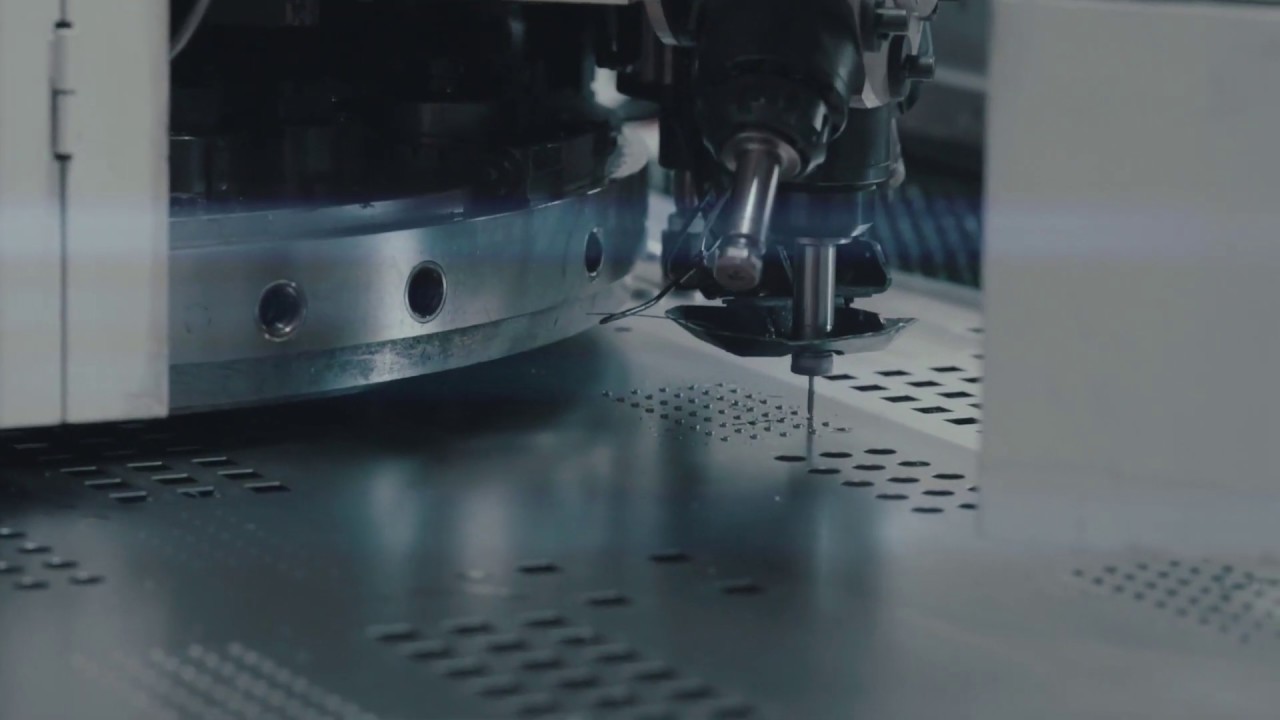

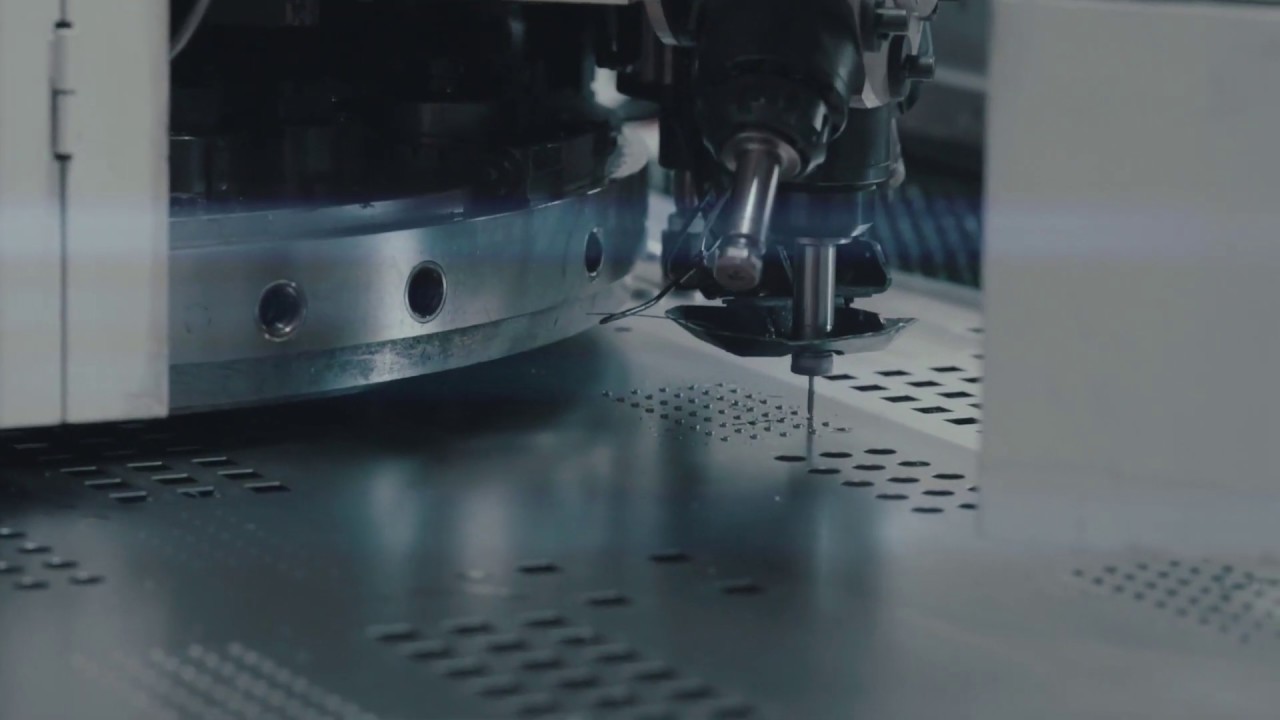

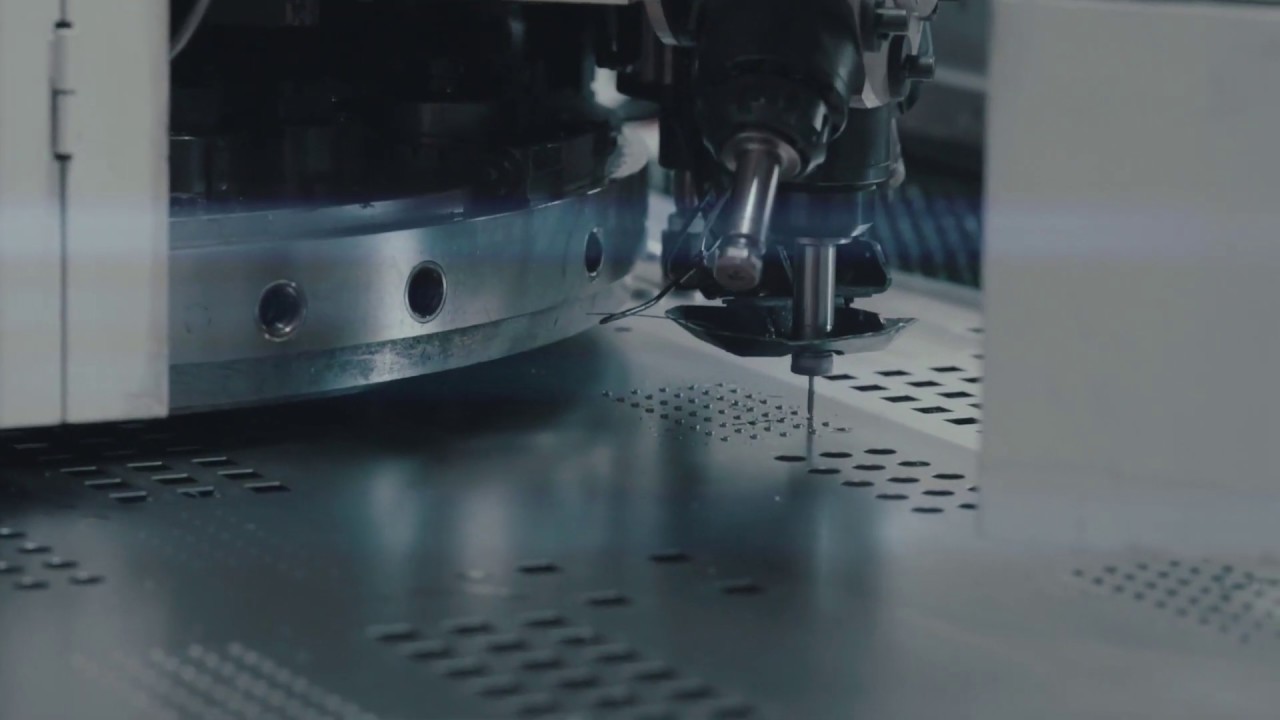

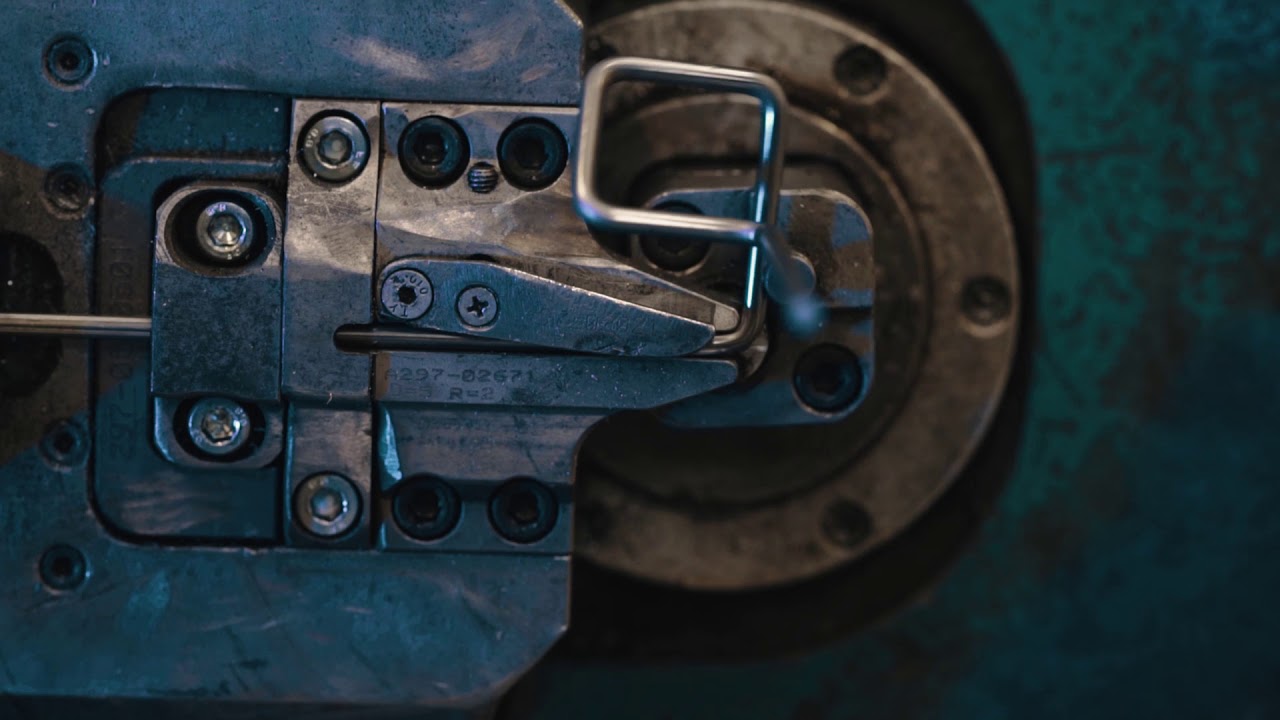

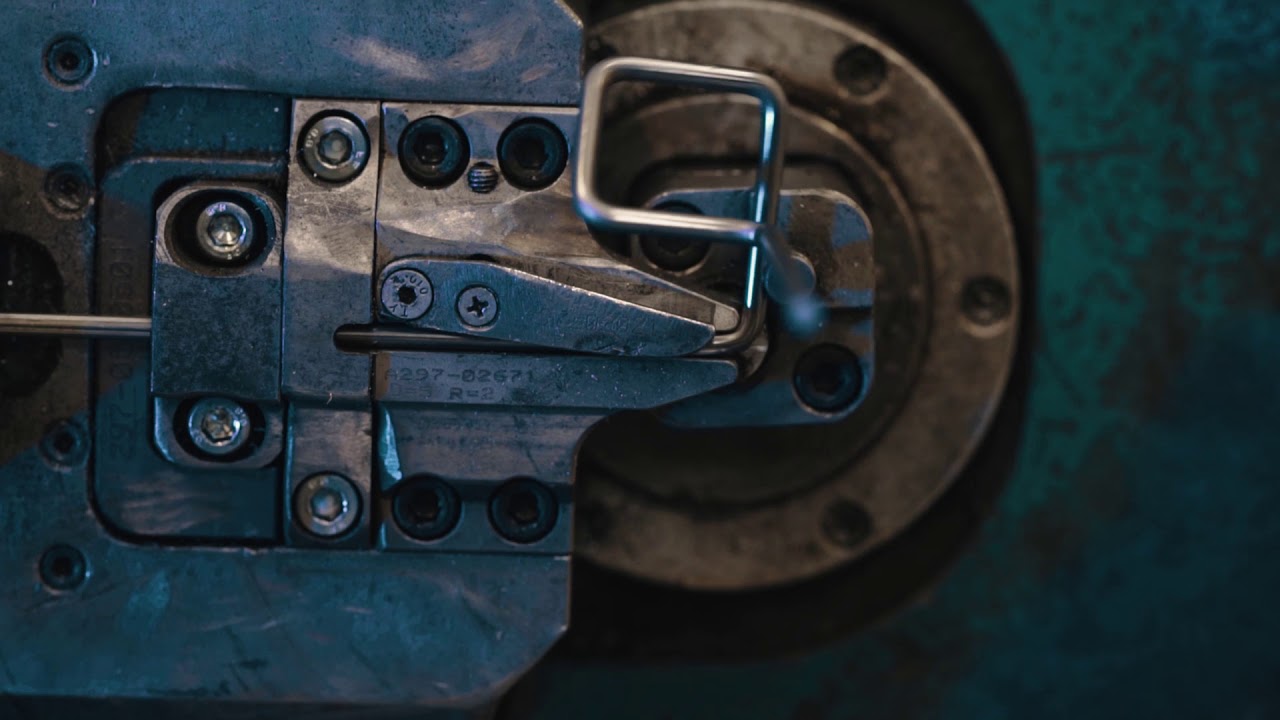

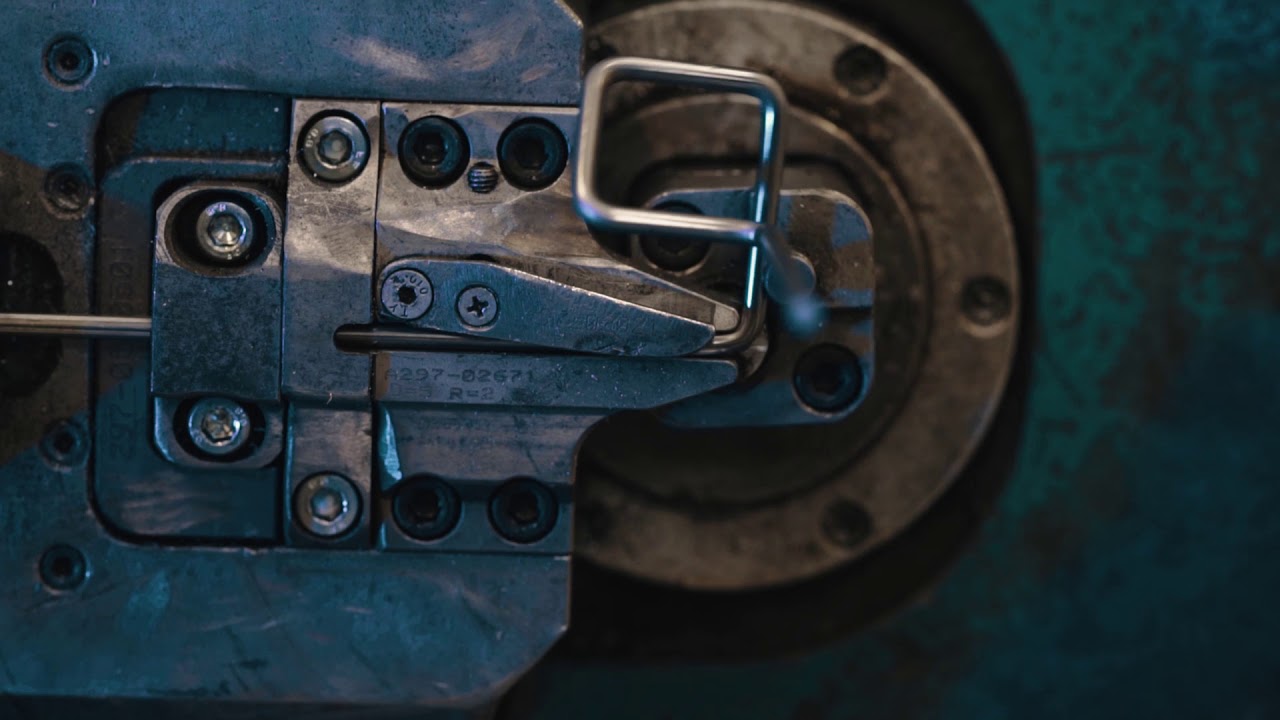

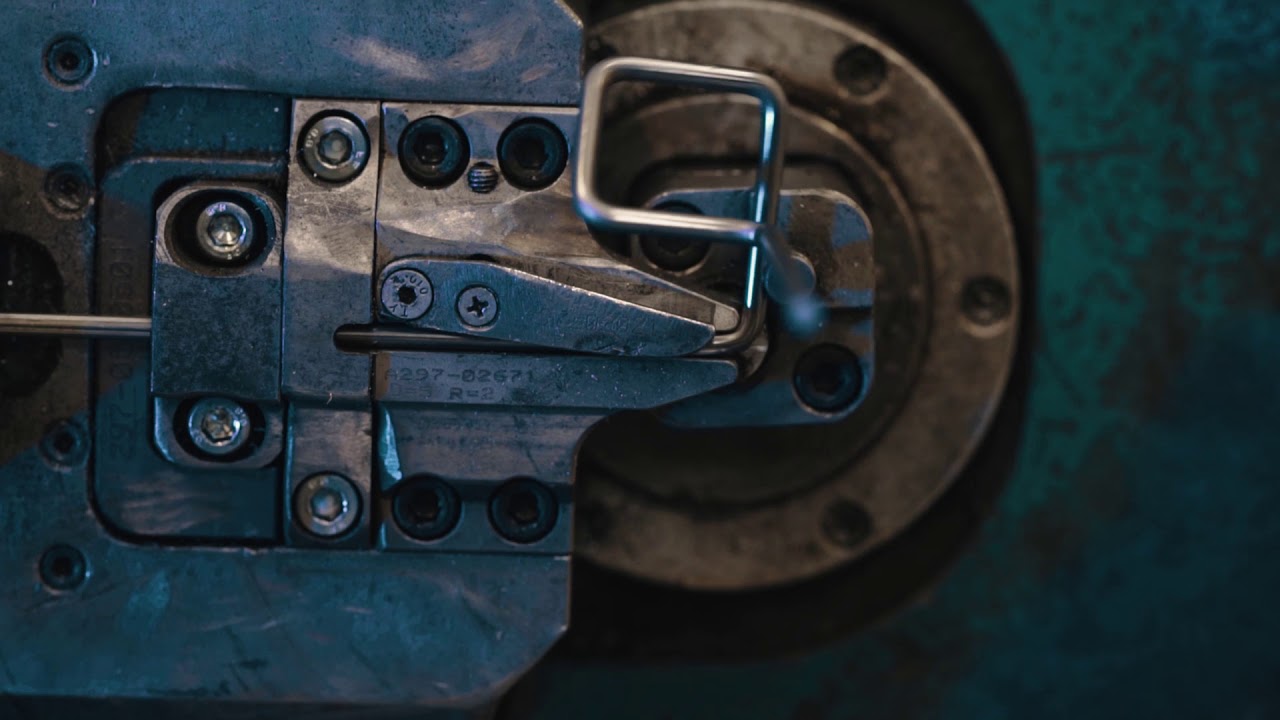

PUNCHING

Looking for ways to increase production capabilities we had to face the challenge of punching metal elements. Professional approach, high level of quality of the process and at the same time energy savings are guaranteed by MOTORUM 2548 punching machine used by our qualified staff.

Thanks to this device, we are able to punch the most complex shapes in a precise and repeatable manner. At the same time, the model chosen by us has numerous improvements in terms of configuration and programming which ensures fast execution of all orders. An additional advantage of our machine is the automated system of loading and unloading, which enables constant work-flow without the presence of an operator. As a result it is possible to lower costs of the entire production process and gain a positive impact on the environmental protection issues.

PUNCHING

PUNCHING

Looking for ways to increase production capabilities we had to face the challenge of punching metal elements. Professional approach, high level of quality of the process and at the same time energy savings are guaranteed by MOTORUM 2548 punching machine used by our qualified staff.

. Thanks to this device, we are able to punch the most complex shapes in a precise and repeatable manner. At the same time, the model chosen by us has numerous improvements in terms of configuration and programming which ensures fast execution of all orders. An additional advantage of our machine is the automated system of loading and unloading, which enables constant work-flow without the presence of an operator. As a result it is possible to lower costs of the entire production process and gain a positive impact on the environmental protection issues.

PUNCHING

CNC BENDING

Bending technologies are one of the most complex and demanding processes and at the same time very common in processes of production of light, functional metal structures. This stage is very important due to the need of maintaining the highest safety parameters and aesthetics of the products manufactured and finished in such a technology. At DABEW we have several machines for precise bending of sheets and wire.

Those are press brakes and a wire bending centre. All our devices operate based on modern numerical control systems (CNC). It gives the possibility of very fast, precise and highly repeatable manufacture of various complex shapes. Thanks to CNC technologies, we can guarantee equality of products within one production series and a technical compatibility of the project. The obvious advantage of bending processes using CNC is the ability to achieve the shortest time needed for completion of the project. It wouldn’t be possible without highly competent, qualified and experienced operators at DABEW.

CNC BENDING

CNC BENDING

Bending technologies are one of the most complex and demanding processes and at the same time very common in processes of production of light, functional metal structures. This stage is very important due to the need of maintaining the highest safety parameters and aesthetics of the products manufactured and finished in such a technology. At DABEW we have several machines for precise bending of sheets and wire.

Those are press brakes and a wire bending centre. All our devices operate based on modern numerical control systems (CNC). It gives the possibility of very fast, precise and highly repeatable manufacture of various complex shapes. Thanks to CNC technologies, we can guarantee equality of products within one production series and a technical compatibility of the project. The obvious advantage of bending processes using CNC is the ability to achieve the shortest time needed for completion of the project. It wouldn’t be possible without highly competent, qualified and experienced operators at DABEW.

CNC BENDING

TIG / MIG WELDING

The history of our company is represented by continuous improvement of steel processing and manufacturing processes of products from this material. We are offering a welding processes at the highest level resulting from a vast experience, cooperation and constant improvements of our professional staff and team building strategies. At DABEW we have well-organized welding workstations which are a crucial part of technological production stages. We employ qualified professionals who are able to join steel parts by several welding methods.

• TIG - joining metal elements using a non-consumable tungsten electrode in an inert gas atmosphere

• MIG - joining metal elements using a consumable electrode in an inert gas atmosphere

• MAG - combining metal elements using a consumable electrode in an active gas atmosphere

The company meets the requirements of the welding process PN-EN ISO 15609-2 standard

TIG / MIG WELDING

GRINDING

The quality of all utilitarian surfaces and edges is one of the criteria determining the approval for our products before leaving the factory. For this reason, grinding is a necessary and very important production stage. Products like shop shelves must be particularly carefully prepared in terms of safety, hygiene and aesthetics. The special care and precise finishing are our trademarks and represent undisputed sales values to our customers.

At DABEW we know that properly organized workstations are one of the most important processes of the technological path. Our employees are aware of the importance of careful finishing stages of the production phase. Thanks to this we can assure top quality that both the customer and the user appreciate. Many years of experience taught us about the importance of the last stages of production that is why they are supervised by qualified staff. Under the watchful eyes and in hands of experienced specialists mechanical tools help to finish the product millimetre by millimetre.

GRINDING

GRINDING

The quality of all utilitarian surfaces and edges is one of the criteria determining the approval for our products before leaving the factory. For this reason, grinding is a necessary and very important production stage. Products like shop shelves must be particularly carefully prepared in terms of safety, hygiene and aesthetics. The special care and precise finishing are our trademarks and represent undisputed sales values to our customers.

At DABEW we know that properly organized workstations are one of the most important processes of the technological path. Our employees are aware of the importance of careful finishing stages of the production phase. Thanks to this we can assure top quality that both the customer and the user appreciate. Many years of experience taught us about the importance of the last stages of production that is why they are supervised by qualified staff. Under the watchful eyes and in hands of experienced specialists mechanical tools help to finish the product millimetre by millimetre.

GRINDING

POWDER COATING

The last stage of the technology process is the powder coating. At DABEW some of the most technologically advanced, fully automated powder coating lines are used for this process, thanks to which our products are very aesthetic and at the same time fully protected against corrosion and chemical agents. We offer powder painting of aluminium, steel and galvanized elements in three gloss levels and in all RAL colours.

In our company, we approach the finishing stages in a very careful and responsible manner therefore the whole painting process is preceded by additional treatments, improving the cleanliness and adhesion of the surfaces. At the same time, we are constantly improving all stages of production in order to be able to achieve reliable quality and meet required deadlines. Our paint shop meets all requirements to maintain stated quality.

POWDER COATING

POWDER COATING

The last stage of the technology process is the powder coating. At DABEW some of the most technologically advanced, fully automated powder coating lines are used for this process, thanks to which our products are very aesthetic and at the same time fully protected against corrosion and chemical agents. We offer powder painting of aluminium, steel and galvanized elements in three gloss levels and in all RAL colours.

In our company, we approach the finishing stages in a very careful and responsible manner therefore the whole painting process is preceded by additional treatments, improving the cleanliness and adhesion of the surfaces. At the same time, we are constantly improving all stages of production in order to be able to achieve reliable quality and meet required deadlines. Our paint shop meets all requirements to maintain stated quality.

POWDER COATING